Our factory has ISO class 1 super clean room, providing manufacturing environment suitable for life science field.

Technologies CSCRIE technologies, factories and equipment

ISO class 1 super clean room

Precision punching technology

It excels in precision punching of tape and film, and can be processed by combining multiple materials.

・For checking shape and design, plotter processing that does not require die flexibly support prototypes.

・Continuous punching machine with CCD camera allows to process roll printing products with high accuracy.

・Shapes that cannot be machined at one time can be machined twice, three times or multiple times while accurately aligning.

・With processing in the clean room, we can handle products that dislike dust and foreign objects.

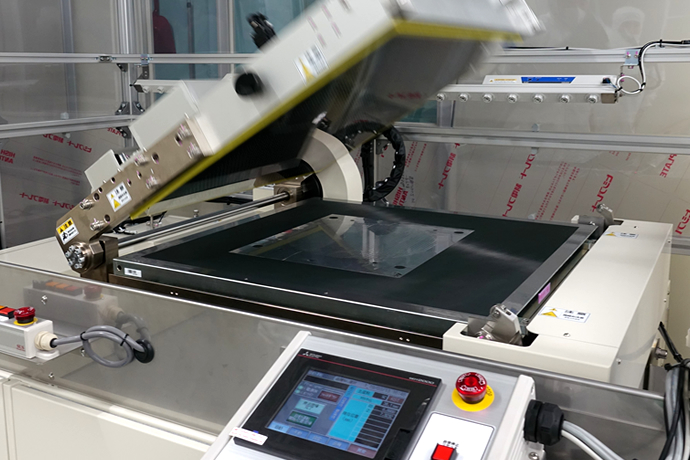

Bonding technology

Sheet lamination and precision bonding of molded parts and microfabricated double-stick tapes are possible.

Equipment

1. Laminating machine

2. Molecular bond machine

3. Spin coater

4. Pressure degassing machine

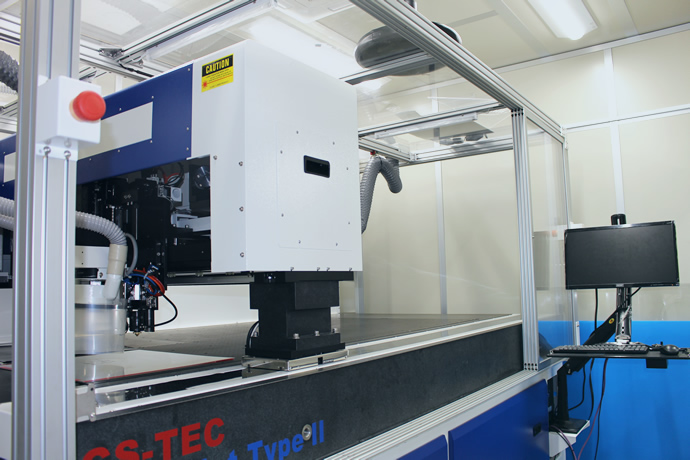

Laser micro process technology

Possible to make micro holes, channels and patterns on DNA and microfluidic chips.

Equipment

1. Deep UV laser

– Process range: 300×300mm

– Beam diameter: approx. 7um

– Ultrafine and non-heat process

– Alignment camera

2. UV, GR and IR with picosecond laser

– Process range: 300×300mm

– Beam diameter: approx. 12-17um

– Micro and non-heat process

– Alignment camera

3. CO2 laser

– Process range: 1000×2000mm

– Beam diameter: approx. 220um

– Large size and thick materials are available